CNC machines are typically used for cutting hard materials and other items to provide the proper shape. There are a lot of CNC machines available on the market today. In this article, we suggest some of the best CNC machines. Shortly, we have added cheap and some of the best CNC machines for woodworking.

You may see that the market offers every sort of CNC machine. Thus, cutting, carving, and engraving materials at home or in your shop are possible now.

Being a beginner, you can get some ideas about some of the best CNC machines for beginners. Likewise, as a hobbyist, you would certainly be interested in some of the best CNC machines for hobbyists. Included in the list, after complete research and considering product reviews, we have come up with some of the ideas for all and the best CNC machines that the market offers today:

Best CNC Machines For Woodworking

1. Genmitsu CNC Pro Router

Sturdy and strong are two words that best describe this CNC 3018-Pro router. The router uses high-performance, open-source software for controlling movement and runs on Arduino. Thus, it is a versatile CNC with easy assembly. You can easily use this for all types of plastics, aluminum, PVs, PCBs, woods, etc. however, make sure not to use it for hard materials. The kit has basic instructions that can quickly help you assemble the set.

This CNC router is strongly built for heavy-duty and long usage performance, making input/output stable even when working for a long time. The machine supports a significant footprint and cutting area. However, those who don’t wish to connect it to their computers can order the offline controller. With the offline controller, you can manually adjust the X, Y, and Z-axis without connecting to the laptop and downloading files.

Shortly, this is the kit you can buy. It is the best machine for the price. With an integrated mainboard and custom software, communication between the software and hardware is seamless by design. Thus, take your creativity to the next level with this masterpiece.

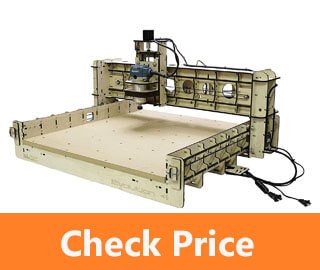

2. BobsCNC Evolution 4 CNC Router

Here comes another CNC router with the best design and working area of 24 x 24 x 3.3 inches. The Bobs CNC can be used on hard plastic or light-strength wood. Due to its rigid laser-cut frame, you would love this kit and work on it.

Moreover, the machine is rigid and sturdy, with an excellent design. The overall setup is easy and quick. You can manually assemble the kit. Overall, the quality of materials included in the kit is ideal for a starter machine.

Shortly, this is the best CNC router one can get. It is entirely worth the money. The spatial movements are quick and smooth. Moreover, it comes with special manual instructions. Many YouTube videos are available that will take you through software installation.

3. SainSmart Genmitsu CNC Router Machine

If you are searching for a compact CNC machine, then the SainSmart Genmitsu CNC router is all you need. This kit perfectly fits your requirements. It is both practical and efficient, loaded with tons of incredible features. It is pre-assembled with no fuss with assembly. You can get started within 15 minutes of receiving it.

However, the kit provides enough stability for milling a more comprehensive range of materials. Likewise, the cleanup is also easy due to the acrylic safety baffles. However, ensure that you have prior knowledge of using GRBL v1.1 software to run this CNC machine.

The readouts are evident on the 1.8-inch display. Thus, your dependability on the software vanishes. Hence, you can easily take control of the 3018-PROVer Desktop CNC machine with controls at your fingertips. Likewise, manual control is also easy.

The kit also features an emergency stop control. Thus, it is easy to access and visible for the quick shutdown of the machine. Similarly, you would evidence optocouplers added to provide extra protection to the mainboard for the durability of this machine. Shortly, the device became fully stable and sturdy. It has a body crafted thoroughly from aluminum adding to its longevity.

4. Upgrade Version CNC 3018 Pro

Here comes an upgraded version CNC 3018 pro router that features a Driver Chip, Fixed Heat Sin, External Fan, and Sturdy Casing to extend the life of the control board. It is ideal for carving wood, plastic, acrylic, PCB CCL, and soft metals like copper, aluminum, and other materials. However, make sure not to use it for carving hard metal, jade, and other hard texture items.

Additionally, the new control board is covered and also has a fan. There are connections for a laser attachment; similarly, each panel has open connectors for the offline controller. Moreover, the kit includes an English manual and software. Likewise, the CNC3018 Pro is straightforward to install and comes with quick assembly. It may hardly take you 20 minutes to assemble it and get started.

This set is ideal for beginners as you can operate it without connecting to the computer. The package includes an electronic control board, stepper motors, a frame, a power supply, and more. The SD card reader is there to write into the root directory G-code file or NC file.

5. CNC 3018 Pro Milling Machine

With an excellent design and generous working area of 30x18x14.5 cm, the upgraded version CNC 3018 Pro GRBL is one machine you need the most. Besides the working area, the tool features a spindle motor. This machine is compatible with various programs and suitable for materials like plastics, wood, MDF board, PCV, and composite plywood.

Generally, this machine is ideal with a whole set of new control boards. It is durable and contains self-contained short-circuit protection, making it even more long-lasting. It features an integrated driver chip, fixed heat sink, external fan, and sturdy casing to add to the longevity of the control board.

What else does one need other than this versatile router machine? It is ideal for all sorts of materials, but the drill bit can’t engrave hard materials, jade, etc. Likewise, the device also has an offline controller with a 1G capacity. You don’t need to connect to a computer to complete the job. You can place this router in your garage or workshop.

When it comes to its assembly, you will not find it very difficult. This machine works well with easy and friendly software with a logical setup. You can also witness the cutting bid location in real time. Moreover, the emergency stop button provides maximum security and safer operation. Thus, it is a good value for money.

Best CNC Machines For Woodturning Buyer’s Guide

Before buying a CNC machine, there are several features that one needs to consider. Getting a suitable CNC machine is not an easy task. However, getting the best and most precise model for you is essential. So, let’s discuss one by one as what are the most critical features you need to consider while making a purchase;

1. Working Area

The working area of the CNC machine is one of the crucial factors you need to consider. It decides how large your designs could be. Well, the BobsCNC E4 machine is one with the largest working area. On the contrary, MY SWEETY CNC machine 1610 offers the smallest working area.

2. Spindle / Router

You must go for a spindle if you need a router machine for industrial or heavy-duty operation. The spindles are pretty expensive. They generate more cutting power as compared to a router. Moreover, the spindles feature precision bearing that gives smooth and accurate cuts. On the other hand, the CNC routers are not very expensive and suitable for working with spindle kits. Typically, the CNC routers are best at handling light-duty jobs. So, you need to decide whether you need a CNC machine for heavy-duty jobs or commercial purposes.

3. Software

Before deciding on a specific model, you must check its software compatibility. One needs to match the operating system list and your machine’s compatibility. However, we recommend you choose a model equipped with GRBL that is easy to use and comes with the most reasonable programs.

4. The Weight of the Machine

The CNC machines primarily use aluminum, polymer composite, and cast iron. So, it would help if you decided upon the machine depending on your needs. The cast iron machine is the best for dealing with more demanding jobs. For other, more straightforward activities, you may prefer different materials.

5. Speed of Machine

It would help to consider the machine’s feed rate before purchasing one. The speed of the machine decides the rate at which you can cut the material during the entire manufacturing process. So, based on your requirements, you also need to consider this factor.

6. Spare Parts Availability

As there are always chances of wear and tear in the case of every machine. The same is the case with the CNC router machines. So the machines with spare parts available on the market are mostly preferred. Make sure to go for the brands with their spare parts readily available. Likewise, the technicians can quickly repair the machines.

What is the best CNC machine for Beginners?

Well, there are all sorts of CNC machines available today. However, some of the best CNC machines for beginners are BobsCNC: E3 CNC Router Kit, 3018 GRBL control DIY mini CNC, and SainSmart’s Genmitsu CNC 3018-PRO.

Which is the best CNC router machine?

Some of the best CNC router machines you can find on the market today are Sainsmart, BobsCNC, Upgrade Version CNC 3018 Pro, Genmitsu, etc. Both professionals and beginners can trust these CNC router machines.

What is the most expensive CNC machine?

There are a wide variety of CNC machines available. However, when it comes to the most expensive CNC machines, then the 5-axis CNC machines are the most costly. It demands extra skill and costs to use this five-axis CAM software.

Is CNC easy to learn?

Well, it starts with fundamental CNC programming that is very easy to learn. You must have a pretty basic knowledge of math and a command of how machining functions. It may take you a few days to know everything. Moving towards intermediate programming skills may take you a year. At the same time, Advanced CNC programming may take you more years to learn thoroughly.

How do I choose a CNC machine?

You need to check the machine’s weight and the materials used in its construction. Secondly, the working radius is another essential factor to be considered. Other factors include the machines’ speed, power consumption, and availability of spare parts. Here are some crucial tips for selecting a suitable CNC machine.

What can a CNC router do?

A CNC router is a Computer Numerical Control that is a computer-controlled cutting machine. It is usually used for cutting, engraving, and carving various materials to give them the proper shape. You can use CNC routers on materials like wood, composites, aluminum, steel, plastics, glass, etc.

Final Thoughts

Thus, CNC machines are great due to precision and savings on manufacturing expenses. They allow you to get things done in no time. You can use them to reduce waste and increase your productivity with total efficiency. Moreover, CNC machines are ideal for both beginners and hobbyists.

The CNC mentioned above is ideal for accurate precision and the best performance. To add more, it depends on your requirements regarding which CNC machine you need for the money. There are a lot of CNC machines that come at very affordable prices.

Generally, CNC machines are expensive and are a one-time investment. So, it is better to consider all the factors before purchasing and sleet the one that will last longer and better serve your needs.